Pipe Relining/ No Dig Solution/ Reline or Renew - Paarl

Friday, 20 January 2023

Item details

City:

Paarl, Western Cape

Offer type:

Offer

Item description

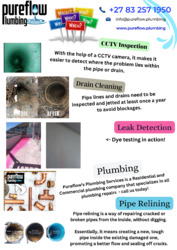

Are you having trouble with broken pipes or a blocked drain?

In the past, your only option would be to have them excavated. Today, the simple process of pipe relining is often the preferred option.

With traditional trenching, you are usually required to pay a plumbing company to dig up the street or walls to remove the pipelines and replace them.

However, with pipe relining you can simply have them relined using a flexible tube coated with resin which is pulled into the damaged pipe and inflated. The resin then hardens, creating a pipe within a pipe.

This process typically involves digging just one access hole.

What is Pipe Relining?

Pipe Relining is a trenchless rehabilitation method used to repair existing pipelines. It is a jointless, seamless pipe lining within an existing pipe. This process does not require excavation to rehabilitate a pipeline that is either leaking or structurally compromised

Pipe Relining or Pipe Renewal

Nu Flow has patented its pull-in-place structural lining process along with its epoxy coating system. The easiest way to determine which process is used for a particular project or scope would be by breaking the piping systems into two categories, pressurized and non-pressurized piping systems.

Because Nu Flow has the unique ability to fix both pressurized piping systems and non-pressurized piping systems using existing access points, Nu Flow offers the most viable and least disruptive option for pipe renewal.

How does the Pipe Relining process work?

The process includes a special epoxy which acts as both the finish coat for the liner and the adhesive to bond the liner to the concrete. The liner is also bonded with an embedded fastener system using a proprietary anchoring system which prevents delamination and allows for easy repair of the liner. Nu Flow also makes products including – sewage piping and fittings, manholes, pipe spools, etc., as well as manufacturing access covers and sanitary valves.

Trenchless “no dig” technology

Known as trenchless repair, old pipes (or their remnants) are usually left in place while a new pipe is simply formed or pulled inside. “When we replace the entire pipe,” he says, “it’s a much more disruptive process and doesn’t tend to have the longevity of a repair.” Trenchless technology has been around for decades but has gained popularity in recent years as contractors have become more adept at excavating in confined spaces. “It’s a technique that’s growing very rapidly,” he says.

In the past, your only option would be to have them excavated. Today, the simple process of pipe relining is often the preferred option.

With traditional trenching, you are usually required to pay a plumbing company to dig up the street or walls to remove the pipelines and replace them.

However, with pipe relining you can simply have them relined using a flexible tube coated with resin which is pulled into the damaged pipe and inflated. The resin then hardens, creating a pipe within a pipe.

This process typically involves digging just one access hole.

What is Pipe Relining?

Pipe Relining is a trenchless rehabilitation method used to repair existing pipelines. It is a jointless, seamless pipe lining within an existing pipe. This process does not require excavation to rehabilitate a pipeline that is either leaking or structurally compromised

Pipe Relining or Pipe Renewal

Nu Flow has patented its pull-in-place structural lining process along with its epoxy coating system. The easiest way to determine which process is used for a particular project or scope would be by breaking the piping systems into two categories, pressurized and non-pressurized piping systems.

Because Nu Flow has the unique ability to fix both pressurized piping systems and non-pressurized piping systems using existing access points, Nu Flow offers the most viable and least disruptive option for pipe renewal.

How does the Pipe Relining process work?

The process includes a special epoxy which acts as both the finish coat for the liner and the adhesive to bond the liner to the concrete. The liner is also bonded with an embedded fastener system using a proprietary anchoring system which prevents delamination and allows for easy repair of the liner. Nu Flow also makes products including – sewage piping and fittings, manholes, pipe spools, etc., as well as manufacturing access covers and sanitary valves.

Trenchless “no dig” technology

Known as trenchless repair, old pipes (or their remnants) are usually left in place while a new pipe is simply formed or pulled inside. “When we replace the entire pipe,” he says, “it’s a much more disruptive process and doesn’t tend to have the longevity of a repair.” Trenchless technology has been around for decades but has gained popularity in recent years as contractors have become more adept at excavating in confined spaces. “It’s a technique that’s growing very rapidly,” he says.